Comprehensive product development and supply chain optimization services powered by 15 years of experience and deep industry expertise

From concept to market, we provide integrated solutions that streamline your product development journey and optimize your supply chain operations

Optimize your entire supply chain with our extensive network of 500+ verified factories and direct supplier relationships across Shenzhen's manufacturing ecosystem.

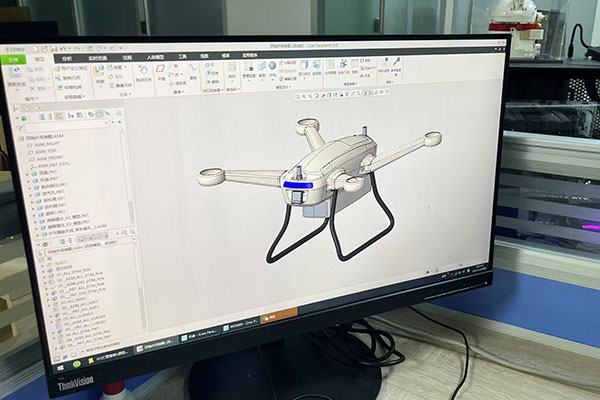

Professional mechanical engineering services from concept sketches to production-ready designs with comprehensive technical documentation and DFM optimization.

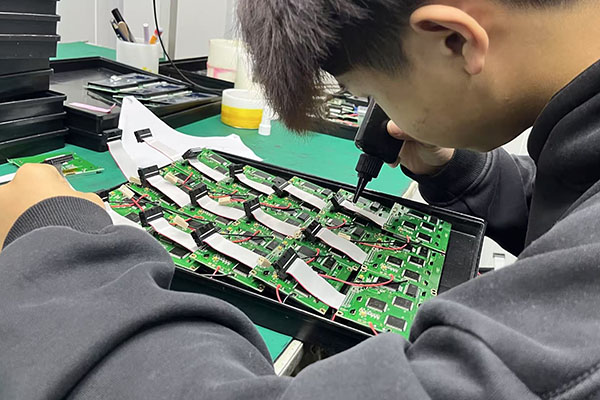

Complete electronic system design including PCB layout, firmware development, and compliance testing for global market standards including FDA, CE, and RoHS.

Accelerated prototyping services with multiple manufacturing methods to validate your designs quickly and efficiently, reducing time-to-market by 50%.

End-to-end manufacturing solutions from small batch production to high-volume manufacturing with comprehensive quality assurance and logistics coordination.

A streamlined approach that connects all our core solutions into a cohesive product development journey

Market research, requirements analysis, and initial design concepts

Detailed engineering design and rapid prototype development

Factory selection, supply chain optimization, and quality systems

Manufacturing execution and scalable production management

Our comprehensive approach eliminates the complexity of managing multiple vendors while ensuring seamless coordination across all aspects of product development.

Reduce development cycles by 30-50% through integrated workflows and parallel processing

Achieve 15-30% cost savings through direct supplier relationships and optimized processes

Maintain defect rates below 1.5% through comprehensive quality management systems

Let's discuss how our integrated solutions can accelerate your product development and optimize your supply chain operations