Complete Supply Chain Solutions

We provide end-to-end services to optimize your product development costs and accelerate time-to-market with our proven expertise in China manufacturing.

Cost Reduction Programs

Value engineering analysis, design optimization, and strategic sourcing to reduce unit costs by 30-50%.

- • Material cost analysis

- • Alternative sourcing

- • Design for manufacturing

New Product Introduction

From concept to mass production with parallel engineering and DFM optimization.

- • Concept design support

- • Prototype development

- • Tooling & mold development

Supply Chain Management

Strategic procurement and supplier management with 500+ verified factories network.

- • Supplier screening & audit

- • Quality control systems

- • Logistics optimization

Production Optimization

Lean manufacturing implementation to eliminate waste and improve operational efficiency.

- • Process improvement

- • Waste elimination

- • Efficiency enhancement

Your Trusted Partner in China

Based in Shenzhen, the heart of China's manufacturing ecosystem, we deliver measurable results through process-driven excellence and deep supply chain expertise.

Our Manufacturing Network

Our verified factory network spans across Guangdong province, covering electronics, medical devices, IoT hardware, and industrial components manufacturing.

Quality Assurance Process

Supplier Audit & Verification

Comprehensive factory assessment including certifications, capabilities, and quality systems.

In-Process Quality Control

Regular inspections during production with detailed quality reports and corrective actions.

Final Inspection & Testing

Pre-shipment inspection ensuring <1.5% defect rate with comprehensive test reports.

Transforming Businesses Worldwide

From innovative startups to Fortune 500 companies, we've helped businesses across the globe optimize their supply chains, reduce costs, and accelerate growth through strategic partnerships

Total Cost Savings

Achieved through strategic supplier optimization and value engineering across all client portfolios

Revenue Growth

Startups scaled from prototype to mass production, achieving sustainable growth milestones

Time-to-Market

Accelerated product development through parallel engineering and optimized workflows

Global Reach

Serving clients worldwide with localized support across North America, Europe, and APAC

"Working with Feiliz has been transformational for our business. Their deep understanding of both Western business practices and Chinese manufacturing capabilities, combined with their commitment to quality and transparency, makes them an invaluable partner."

Join the growing community of industry leaders who trust Feiliz as their strategic partner for supply chain optimization, cost reduction, and accelerated growth

"Feiliz helped us reduce our medical device manufacturing costs by 40% while maintaining FDA compliance. Their attention to detail and process management is exceptional."

"From prototype to mass production in just 12 weeks. Feiliz's network and expertise saved us 6 months of development time and significant costs."

"As a startup, we needed a reliable partner in China. Feiliz became our extended team, managing our entire supply chain with transparency and efficiency."

Success Stories

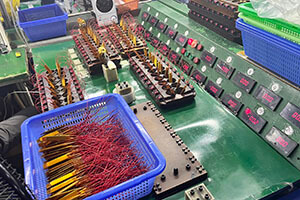

Electronics Cost Engineering & Performance Enhancement

Through circuit architecture redesign and component optimization, we reduced PCBA costs by 40% for a client's smart controller while enhancing product performance and reliability. This comprehensive approach involved strategic component sourcing and manufacturing process improvements.

View Full Case Study →

Fast-Track Tooling & Time-to-Market Acceleration

Utilizing rapid prototyping and simplified tooling solutions, we reduced our client's new product development cycle from 12 months to 6 months, achieving 60% tooling cost savings while enabling faster market validation and product iteration.

View Full Case Study →

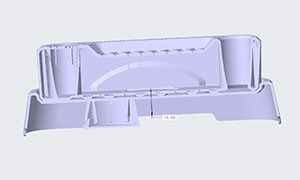

Design for Manufacturing (DFM) Optimization

Through comprehensive internal structure redesign, we streamlined manufacturing processes from 8 steps to 5, improved material utilization by 30%, reduced assembly time by 50%, and achieved an overall 35% cost reduction while maintaining product quality.

View Full Case Study →Get Your Free Cost Analysis

Discover how much you can save on your next project. Our experts will analyze your current costs and provide a detailed optimization plan.

We respect your privacy. Your information will never be shared with third parties.

What You'll Receive:

Free Cost Analysis Report

Detailed breakdown of potential savings for your specific product category with actionable recommendations.

China Sourcing Toolkit

Comprehensive 41-page PDF with systematic frameworks, practical tools, and proven methodologies to optimize procurement processes.

Strategy Consultation Call

30-minute one-on-one call with our supply chain experts to discuss your specific challenges.

🎯 Immediate Access

Get instant access to our "Quick Cost Reduction Checklist" via email, plus all other resources within 24 hours.

Ready to Reduce Your Costs by 30-50%?

Join 200+ companies that have optimized their supply chains with Feiliz. Start your cost reduction journey today.